The process of painting Fremont area commercial properties comes with numerous hazards that can impact the health and safety of workers. These include the risks associated with chemical exposure and the physical dangers of working at heights. Understanding these possible hazards is important in maintaining a safe workplace. These challenges can be found in any type project such as a larger interior painting project in Sunnyvale to a concrete ceiling repair in Union City.

In this article, we’ll discuss the risks involved in commercial painting. We’ll highlight the importance of proper safety measures, training, and regulatory compliance. By learning about these, businesses can protect employees and ensure a safer and more efficient painting process.

Types of Hazards Associated with Painting in Commercial Settings

Understanding and addressing the various hazards associated with painting in commercial settings is crucial for maintaining a safe work environment. Here are the different types of hazards you should know about:

1. Chemical Hazards

One of the most significant hazards in commercial painting is exposure to chemicals found in paints, solvents, and other related products. These substances often contain volatile organic compounds (VOCs), which can be harmful when inhaled. Prolonged exposure to VOCs can lead to respiratory problems, headaches, dizziness, and even long-term health issues such as liver and kidney damage. Proper ventilation, the use of less toxic materials, and personal protective equipment (PPE) such as respirators are essential in mitigating these risks.

2. Physical Hazards

Commercial painting often involves working at heights, using ladders, scaffolding, or lifts. This introduces the risk of falls, which can result in serious injuries or fatalities. Ensuring all equipment is properly maintained and workers are trained in its safe use is critical. Additionally, painters may encounter other physical hazards such as falling objects, electrical hazards when working near power lines, and ergonomic issues from repetitive motions or awkward postures.

3. Fire and Explosion Hazards

Many paints and solvents are flammable, creating a risk of fire or explosion if proper precautions are not taken. Ensuring work areas are free from open flames, sparks, and other ignition sources is essential. Storing flammable materials in accordance with safety regulations and having fire extinguishers readily available can also help prevent accidents. Workers should be trained in properly handling and storing flammable substances to reduce these risks.

4. Health Hazards

In addition to chemical exposure, painters can face other health hazards, such as skin irritation and allergic reactions, from direct contact with paints and solvents. Wearing appropriate PPE, such as gloves and protective clothing, can help minimize skin contact with hazardous substances. Regular health monitoring and providing workers access to medical care can also help manage these health risks.

5. Environmental Hazards

Improper paint and related materials disposal can pose environmental hazards, contaminating soil and water sources. Adhering to proper disposal methods and regulations is essential to prevent environmental damage. Using environmentally friendly products and recycling materials can also reduce the environmental impact of commercial painting projects.

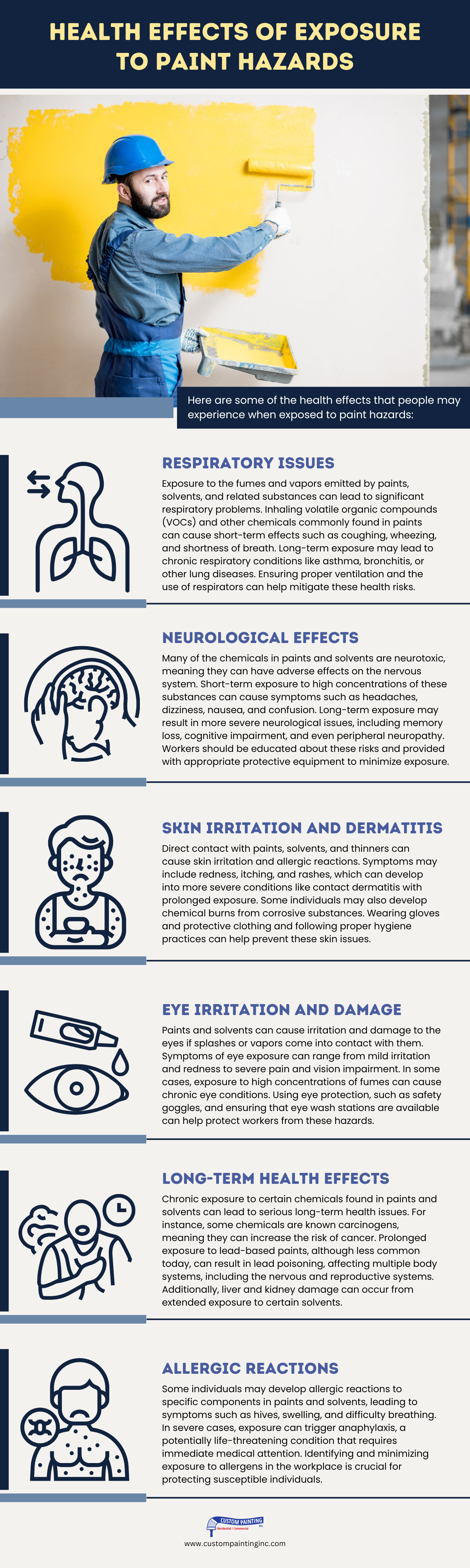

Health Effects of Exposure to Paint Hazards

Here are some of the health effects that people may experience when exposed to paint hazards:

1. Respiratory Issues

Exposure to the fumes and vapors emitted by paints, solvents, and related substances can lead to significant respiratory problems. Inhaling volatile organic compounds (VOCs) and other chemicals commonly found in paints can cause short-term effects such as coughing, wheezing, and shortness of breath. Long-term exposure may lead to chronic respiratory conditions like asthma, bronchitis, or other lung diseases. Ensuring proper ventilation and the use of respirators can help mitigate these health risks.

2. Neurological Effects

Many of the chemicals in paints and solvents are neurotoxic, meaning they can have adverse effects on the nervous system. Short-term exposure to high concentrations of these substances can cause symptoms such as headaches, dizziness, nausea, and confusion. Long-term exposure may result in more severe neurological issues, including memory loss, cognitive impairment, and even peripheral neuropathy. Workers should be educated about these risks and provided with appropriate protective equipment to minimize exposure.

3. Skin Irritation and Dermatitis

Direct contact with paints, solvents, and thinners can cause skin irritation and allergic reactions. Symptoms may include redness, itching, and rashes, which can develop into more severe conditions like contact dermatitis with prolonged exposure. Some individuals may also develop chemical burns from corrosive substances. Wearing gloves and protective clothing and following proper hygiene practices can help prevent these skin issues.

4. Eye Irritation and Damage

Paints and solvents can cause irritation and damage to the eyes if splashes or vapors come into contact with them. Symptoms of eye exposure can range from mild irritation and redness to severe pain and vision impairment. In some cases, exposure to high concentrations of fumes can cause chronic eye conditions. Using eye protection, such as safety goggles, and ensuring that eye wash stations are available can help protect workers from these hazards.

5. Long-term Health Effects

Chronic exposure to certain chemicals found in paints and solvents can lead to serious long-term health issues. For instance, some chemicals are known carcinogens, meaning they can increase the risk of cancer. Prolonged exposure to lead-based paints, although less common today, can result in lead poisoning, affecting multiple body systems, including the nervous and reproductive systems. Additionally, liver and kidney damage can occur from extended exposure to certain solvents.

6. Allergic Reactions

Some individuals may develop allergic reactions to specific components in paints and solvents, leading to symptoms such as hives, swelling, and difficulty breathing. In severe cases, exposure can trigger anaphylaxis, a potentially life-threatening condition that requires immediate medical attention. Identifying and minimizing exposure to allergens in the workplace is crucial for protecting susceptible individuals.

Regulatory Standards and Safety Protocols

Overview of OSHA Regulations Concerning Painting in Commercial Settings

The Occupational Safety and Health Administration (OSHA) in the United States sets forth regulations to ensure the safety and health of workers involved in painting and related activities in commercial settings. OSHA’s standards encompass a wide range of safety measures. These include exposure limits for hazardous substances, requirements for ventilation, and guidelines for the use of personal protective equipment (PPE).

Key OSHA regulations relevant to commercial painting include:

- Hazard Communication Standard (HCS): This regulation mandates that employers provide information about the hazardous chemicals used in the workplace through labels, safety data sheets (SDS), and employee training.

- Respiratory Protection Standard: Employers must provide appropriate respiratory protection to workers exposed to harmful dust, fogs, fumes, mists, gases, smoke, sprays, or vapors.

- Personal Protective Equipment (PPE) Standard: Employers are required to assess the workplace to determine if hazards are present and to select, provide, and enforce the use of suitable PPE.

- Ventilation Requirements: Proper ventilation must be ensured to maintain safe levels of airborne contaminants, particularly in confined spaces or areas with poor natural ventilation.

Globally Recognized Standards and Practices

Beyond OSHA, several internationally recognized standards and regulations govern safety in commercial painting environments. These standards help harmonize safety practices across different countries and industries, ensuring a consistent approach to worker protection.

- ISO Standards: The International Organization for Standardization (ISO) provides guidelines for occupational health and safety management systems. ISO 45001, for instance, outlines requirements for creating a safe and healthy workplace, reducing workplace risks, and enhancing health and safety performance.

- EU Regulations: The European Union has stringent regulations concerning the use of chemicals in the workplace, such as the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation. This framework ensures the safe use of chemicals and the protection of human health and the environment.

- Globally Harmonized System (GHS): The GHS standardizes the classification and labeling of chemicals to ensure consistent information about chemical hazards across countries. This system enhances the understanding and handling chemical substances, contributing to safer workplace practices.

Importance of Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is critical to protecting workers from the various hazards associated with painting in commercial settings. PPE helps mitigate exposure to harmful substances, prevent injuries, and ensure employees’ overall safety and well-being.

- Respirators: These are essential for protecting against inhalation of hazardous fumes, dust, and vapors. Proper fit and selection based on the specific hazard are crucial.

- Protective Clothing: Coveralls, gloves, and footwear provide a barrier against skin contact with hazardous chemicals, reducing the risk of irritation, burns, and toxic substance absorption.

- Eye and Face Protection: Safety goggles and face shields protect against splashes and airborne particles that can cause eye injuries and irritation.

- Hearing Protection: In environments where noise levels are high, such as during surface preparation, using power tools, earplugs, or earmuffs helps prevent hearing damage.

Adhering to regulatory standards and safety protocols is essential for ensuring the health and safety of workers in commercial painting environments. Compliance with OSHA regulations, globally recognized standards, and the proper use of PPE are critical components of an effective safety strategy.

Best Practices for Managing Painting Hazards in Commercial Settings

Here are some of the best practices on how you can manage painting hazards in commercial settings:

Comprehensive Risk Assessment

The first step in managing painting hazards is conducting a thorough risk assessment. This involves identifying all potential hazards of painting activities, such as chemical exposure, physical risks, and environmental impacts. A comprehensive risk assessment should:

- Evaluate the types of paints, solvents, and chemicals used.

- Identify physical hazards like working at heights or in confined spaces.

- Assess the adequacy of ventilation systems.

- Determine the potential environmental impact of painting activities.

Proper Training and Education

Training is crucial in ensuring that all workers are aware of the hazards they may encounter and know how to protect themselves. Regular training programs should cover the following:

- Hazard communication and understanding safety data sheets (SDS).

- Proper use and maintenance of personal protective equipment (PPE).

- Safe handling, storage, and disposal of paints and solvents.

- Emergency procedures and first aid responses.

Use of Personal Protective Equipment (PPE)

Ensuring that all workers have access to and use appropriate PPE is vital for their safety. Best practices include:

- Providing respirators to protect against inhaling hazardous fumes and dust.

- Ensuring workers wear gloves, protective clothing, and footwear to prevent skin contact with chemicals.

- Supplying safety goggles and face shields to protect against splashes and airborne particles.

- Using hearing protection in noisy environments.

Ventilation and Air Quality Control

Maintaining good ventilation is essential to minimize exposure to hazardous fumes and vapors. Best practices for ventilation include:

- Local exhaust ventilation systems are used to capture and remove contaminants at the source.

- Ensuring general ventilation to dilute airborne contaminants and provide fresh air.

- Regularly inspecting and maintaining ventilation systems to ensure their effectiveness.

Safe Work Practices

Implementing safe work practices can significantly reduce the risk of accidents and exposure to hazards. These practices include:

- Keeping work areas clean and free of clutter to prevent trips and falls.

- Using ladders, scaffolding, and lifts safely and ensuring they are well-maintained.

- Storing flammable materials properly and away from ignition sources.

- Following proper procedures for mixing and applying paints and solvents.

Emergency Preparedness

Being prepared for emergencies can save lives and reduce the severity of incidents. Best practices for emergency preparedness include:

- Developing and regularly updating an emergency action plan.

- Conducting regular drills to ensure workers know what to do in case of a fire, chemical spill, or other emergencies.

- Providing easy access to first aid supplies and ensuring workers are trained in first aid procedures.

- Ensuring fire extinguishers and eye wash stations are readily available and in good working condition.

Environmental Protection

Protecting the environment is also a key aspect of managing painting hazards. Best practices for environmental protection include:

- Using environmentally friendly paints and solvents whenever possible.

- Properly disposing of paint waste and used solvents in accordance with local regulations.

- Implementing spill prevention and response plans to minimize environmental contamination.

- Recycling materials and reducing waste to minimize the environmental footprint of painting activities.

By following these best practices, businesses can effectively manage painting hazards in commercial settings and ensure the safety and health of their workers.

Innovations and Advances in Safer Commercial Painting Practices

Here are some of the innovations and advancements that may help in having safer commercial painting practices:

Development of Low-VOC and No-VOC Paints

One of the most significant advancements in the commercial painting industry has been the development of low-VOC (Volatile Organic Compounds) and non-VOC paints. Traditional paints contain high levels of VOCs, which can evaporate into the air and cause various health issues, such as respiratory problems, headaches, and long-term health effects. Low-VOC and no-VOC paints have been formulated to reduce these emissions, leading to a safer working environment and less environmental impact. These innovative paints offer several benefits:

- Improved Indoor Air Quality: Reducing VOC emissions helps maintain better air quality inside commercial buildings, protecting workers and occupants from harmful fumes.

- Compliance with Regulations: Low-VOC and no-VOC paints help businesses comply with increasingly stringent environmental regulations and standards.

- Enhanced Worker Health: Lower exposure to harmful chemicals reduces the risk of respiratory issues and other health problems among painters.

Advances in Painting Equipment and Safety Gear

Technological advancements in painting equipment and safety gear have significantly improved the safety and efficiency of commercial painting practices. Some notable innovations include:

- High-Efficiency Sprayers: Modern paint sprayers are designed to reduce overspray and minimize waste, ensuring that more paint reaches the intended surface. These sprayers also help reduce the amount of paint fumes released into the air.

- Automated and Robotic Painting Systems: Automation in painting processes has increased precision and consistency while reducing the need for workers to be in hazardous environments. Robotic systems can paint hard-to-reach areas and perform repetitive tasks, enhancing safety and productivity.

- Advanced Respiratory Protection: Innovations in respiratory protection, such as powered air-purifying respirators (PAPRs) and advanced filter technologies, provide better protection against airborne contaminants. These systems offer improved comfort and ease of use for workers.

- Ergonomic Safety Gear: New developments in ergonomic design have led to safety gear that reduces strain and fatigue. For example, lightweight and flexible protective clothing, gloves with better grip and dexterity, and comfortable eye protection enhance worker safety and efficiency.

Emerging Technologies that Improve Safety and Efficiency in Commercial Painting

The commercial painting industry continues benefiting from emerging technologies that enhance safety and efficiency. Some of these cutting-edge technologies include:

- Smart Sensors and Monitoring Systems: Smart sensors can monitor air quality, detect the presence of harmful chemicals, and ensure proper ventilation in real time. These systems can alert workers and supervisors to potential hazards, allowing for timely interventions.

- Virtual and Augmented Reality (VR/AR): VR and AR technologies are being used for training purposes, allowing workers to practice painting techniques and safety protocols in a virtual environment. This reduces the risk of accidents during actual painting tasks and improves overall skill levels.

- Drones for Inspection and Maintenance: Drones equipped with cameras and sensors can inspect large commercial structures, identifying areas that need painting or maintenance. This reduces the need for workers to perform risky inspections at heights or in difficult-to-access areas.

- Eco-Friendly Paint Removal Technologies: Innovative paint removal techniques, such as laser and ultrasonic paint removal, provide safer alternatives to traditional chemical strippers. These methods reduce the release of harmful substances and minimize environmental impact.

Conclusion

Understanding and managing the hazards associated with commercial painting is essential for ensuring a safe and healthy work environment. Businesses can protect their workers and improve efficiency by adhering to regulatory standards, using appropriate PPE, and staying updated with the latest paint technology and equipment innovations. For professional assistance with your commercial painting needs, contact Custom Painting, Inc. at 925-866-9610 or use our contact form.